From Wikipedia"

The two XP-51Bs were a more thorough conversion than the Mustang X, with a tailor-made engine installation and a complete redesign of the radiator duct. The airframe itself was strengthened, with the fuselage and engine mount area receiving more formers because of the greater weight of the Packard V-1650-3, 1,690 lb (770 kg), compared with the Allison V-1710's 1,335 lb (606 kg). The engine cowling was completely redesigned to house the Packard Merlin, which, because of the intercooler radiator mounted on the supercharger casing, was 5 in (130 mm) taller and used an updraught induction system, rather than the downdraught carburetor of the Allison.[17] The new engine drove a four-bladed 11 ft 2 in (3.40 m) diameter Hamilton Standard propeller that featured cuffs of hard molded rubber. To cater for the increased cooling requirements of the Merlin, a new fuselage duct was designed. This housed a larger radiator, which incorporated a section for the supercharger coolant, and, forward of this and slightly lower, an oil cooler was housed in a secondary duct which drew air through the main opening and exhausted via a separate exit flap.

A "duct rumble" heard by pilots in flight in the prototype P-51B resulted in a full-scale wind-tunnel test at NACA Ames Aeronautical Laboratory. This was carried out by inserting the airplane, with the outer wing panels removed, into the 16-foot wind tunnel. A test engineer would sit in the cockpit with the wind tunnel running and listen for the duct rumble. It was eventually found that the rumble could be eliminated by increasing the gap between the lower surface of the wing and the upper lip of the cooling system duct from 1 inch to 2 inches. The conclusion was that part of the boundary layer on the lower surface of the wing was being ingested into the inlet and separating, causing the radiator to vibrate and producing the rumble. The inlet that went into production on the P-51B was lowered even further to give a separation of 2.63 inches from the bottom of the wing. In addition, the shelf that extended above the oil cooler face was removed and the inlet highlight was swept back.

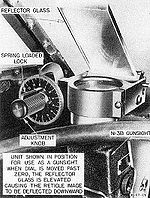

It was decided that new P-51B (NA-102) would continue with the four wing-mounted .50 in (12.7 mm) M2/AN Browning machine guns (with 350 rpg for the inboard guns and 280 rpg for the outboard) first used in the P-51A, while the bomb rack/external drop tank installation was adapted from the A-36 Apache; the racks were rated to be able to carry up to 500 lb (230 kg) of ordnance and were also capable of carrying drop tanks. The weapons were aimed using the electrically illuminated N-3B reflector sight fitted with an A-1 head assembly which allowed it to be used as a gun or bomb sight through varying the angle of the reflector glass. Pilots were also given the option of having ring and bead sights mounted on the top engine cowling formers. This option was discontinued with the later P-51Ds.

The first XP-51B flew on 30 November 1942. Flight tests confirmed the potential of the new fighter, with the service ceiling being raised by 10,000 feet, with the top speed improving by 50 mph at 30,000 ft (9,100 m). American production was started in early 1943 with the P-51B (NA-102) being manufactured at Inglewood, California, and the P-51C (NA-103) at a new plant in Dallas, Texas, which was in operation by summer 1943. The RAF named these models Mustang Mk III. In performance tests, the P-51B reached 441 mph (709.70 km/h) at 30,000 ft (9,100 m). In addition, the extended range made possible by the use of drop tanks enabled the Merlin-powered Mustang to be introduced as a bomber escort with a combat radius of 750 miles using two 75 gal tanks.

The range would be further increased with the introduction of an 85 gal (322 l) self-sealing fuel tank aft of the pilot's seat, starting with the P-51B-5-NA series. When this tank was full, the center of gravity of the Mustang was moved dangerously close to the aft limit. As a result, maneuvers were restricted until the tank was down to about 25 U.S. gal (95 l) and the external tanks had been dropped. Problems with high-speed "porpoising" of the P-51Bs and P-51Cs with the fuselage tanks would lead to the replacement of the fabric-covered elevators with metal-covered surfaces and a reduction of the tailplane incidence.With the fuselage and wing tanks, plus two 75 gal drop tanks, the combat radius was now 880 miles.

P-51C of 311 FG,

China, July 1945, shows the dorsal fin fillet which was fitted to help

counter control problems experienced when the fuselage fuel tank was

fitted.

"Unless a dorsal fin is installed on the P-51B, P-51C and P-51D airplanes, a snap roll may result when attempting a slow roll. The horizontal stabilizer will not withstand the effects of a snap roll. To prevent recurrence, the stabilizer should be reinforced in accordance with T.O. 01-60J-18 dated 8 April 1944 and a dorsal fin should be installed. Dorsal fin kits are being made available to overseas activities"The dorsal fin kits became available in August 1944, and were fitted to P-51Bs and P-51Cs, and to P-51Ds and P-51Ks. Also incorporated was a change to the rudder trim tabs, which would help prevent the pilot over-controlling the aircraft and creating heavy loads on the tail unit.

One of the few remaining complaints with the Merlin-powered aircraft was a poor rearward view. The canopy structure, which was the same as the Allison-engined Mustangs, was made up of flat, framed panels; the pilot gained access, or exited the cockpit by lowering the port side panel and raising the top panel to the right. The canopy could not be opened in flight and tall pilots especially, were hampered by limited headroom. In order to at least partially improve the view from the Mustang, the British had field-modified some Mustangs with clear, sliding canopies called Malcolm hoods (designed by Robert Malcolm), and whose design had also been adopted by the U.S. Navy's own F4U-1D version of the Corsair in April 1944.

A Malcolm Hood-equipped Mustang Mk III flown by Wing Commander Tadeusz Nowierski, CO of 133 (Polish) Wing, RAF Coolham, July 1944.

P-51Bs and P-51Cs started to arrive in England in August and October 1943. The P-51B/P-51C versions were sent to 15 fighter groups that were part of the 8th and 9th Air Forces in England and the 12th and 15th in Italy (the southern part of Italy was under Allied control by late 1943). Other deployments included the China Burma India Theater (CBI).

Allied strategists quickly exploited the long-range fighter as a bomber escort. It was largely due to the P-51 that daylight bombing raids deep into German territory became possible without prohibitive bomber losses in late 1943.

A number of the P-51B and P-51C aircraft were fitted for photo reconnaissance and designated F-6C.