Wednesday, December 20, 2017

Thursday, December 14, 2017

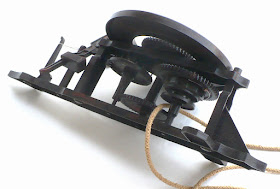

!3th Century Medieval Wheel Clock

Here are some images of Lindberg Models 1/1 scale 13th Century Medieval Wheel Clock. Or was that 15th Century? I guess it would depend on what release you buy.

Now if I can only get the darn thing to work.

From Wikipedia"

The verge (or crown wheel) escapement is the earliest known type of mechanical escapement, the mechanism in a mechanical clock that controls its rate by allowing the gear train to advance at regular intervals or 'ticks'. Its origin is unknown. Verge escapements were used from the 14th century until the mid 19th century in clocks and pocketwatches. The name verge comes from the Latin virga, meaning stick or rod.

Its invention is important in the history of technology, because it made possible the development of all-mechanical clocks. This caused a shift from measuring time by continuous processes, such as the flow of liquid in water clocks, to repetitive, oscillatory processes, such as the swing of pendulums, which had the potential to be more accurate. Oscillating timekeepers are used in all modern timepieces.

The verge escapement dates from 13th-century Europe, where its invention led to the development of the first all-mechanical clocks. Starting in the 13th century, large tower clocks were built in European town squares, cathedrals, and monasteries. They kept time by using the verge escapement to drive the foliot, a primitive type of balance wheel, causing it to oscillate back and forth. The foliot was a horizontal bar with weights on the ends, and the rate of the clock could be adjusted by sliding the weights in or out on the bar.

The verge probably evolved from the alarum, which used the same mechanism to ring a bell and had appeared centuries earlier. There has been speculation that Villard de Honnecourt invented the verge escapement in 1237 with an illustration of a strange mechanism to turn an angel statue to follow the sun with its finger, but the consensus is that this was not an escapement.

It is believed that sometime in the late 13th century the verge escapement mechanism was applied to tower clocks, creating the first mechanical clock. In spite of the fact that these clocks were celebrated objects of civic pride which were written about at the time, it may never be known when the new escapement was first used. This is because it has proven difficult to distinguish from the meager written documentation which of these early tower clocks were mechanical, and which were water clocks; the same Latin word, horologe, was used for both. None of the original mechanisms have survived unaltered. Sources differ on which was the first clock 'known' to be mechanical, depending on which manuscript evidence they regard as conclusive. One candidate is the Dunstable Priory clock in Bedfordshire, England built in 1283, because accounts say it was installed above the rood screen, where it would be difficult to replenish the water needed for a water clock. Another is the clock built at the Palace of the Visconti, Milan, Italy, in 1335. However, there is agreement that mechanical clocks existed by the late 13th century.

The earliest description of an escapement, in Richard of Wallingford's 1327 manuscript Tractatus Horologii Astronomici on the clock he built at the Abbey of St. Albans, was not a verge, but a variation called a 'strob' escapement. It consisted of a pair of escape wheels on the same axle, with alternating radial teeth. The verge rod was suspended between them, with a short crosspiece that rotated first in one direction and then the other as the staggered teeth pushed past. Although no other example is known, it is possible that this design preceded the verge in clocks.

For the first two hundred years or so of the clock's existence, the verge was the only escapement used in mechanical clocks. In the sixteenth century alternative escapements started to appear, but the verge remained the most used escapement for 350 years until mid-17th century advances in mechanics, which also resulted in the invention of the pendulum. Since clocks were valuable, after the invention of the pendulum many verge clocks were rebuilt to use this more accurate timekeeping technology, so very few of the early verge and foliot clocks have survived unaltered to the present day.

How accurate the first verge and foliot clocks were is debatable, with estimates of one to two hours error per day being mentioned, although modern experiments with clocks of this construction show accuracies of minutes per day were achievable. Early verge clocks were probably no more accurate than the previous water clocks, but they did not freeze in winter and were a more promising technology for innovation. By the mid-17th century, when the pendulum replaced the foliot, the best verge and foliot clocks had achieved an accuracy of 15 minutes per day.

Most of the gross inaccuracy of the early verge and foliot clocks was not due to the escapement itself, but to the foliot oscillator. The first use of pendulums in clocks around 1656 suddenly increased the accuracy of the verge clock from hours a day to minutes a day. Most clocks were rebuilt with their foliots replaced by pendulums, to the extent that it is difficult to find original verge and foliot clocks intact today. A similar increase in accuracy in verge watches followed the introduction of the balance spring in 1658.

The verge escapement consists of a wheel shaped like a crown, with sawtooth-shaped teeth protruding axially toward the front, and with its axis oriented horizontally. In front of it is a vertical rod, the verge, with two metal plates, the pallets, that engage the teeth at opposite sides of the crown wheel. The pallets are not parallel, but are oriented with an angle in between them so only one catches the teeth at a time. The balance wheel (or the pendulum) is mounted at the end of the verge rod. As the clock's gears turn the crown wheel, one of its teeth pushes on a pallet, rotating the verge in one direction, and rotating the second pallet into the path of the teeth on the opposite side of the wheel, until the tooth pushes past the first pallet. Then a tooth on the wheel's opposite side contacts the second pallet, rotating the verge back the other direction, and the cycle repeats. The result is to change the rotary motion of the wheel to an oscillating motion of the verge. Each swing of the foliot or pendulum thus allows one tooth of the escape wheel to pass, advancing the wheel train of the clock by a fixed amount, moving the hands forward at a constant rate.

The crown wheel must have an odd number of teeth for the escapement to function. With an even number, two opposing teeth will contact the pallets at the same time, jamming the escapement. The usual angle between the pallets was 90° to 105°, resulting in a foliot or pendulum swing of around 80° to 100°. In order to reduce the pendulum's swing to make it more isochronous, the French used larger pallet angles, upwards of 115°. This reduced the pendulum swing to around 50° and reduced recoil (below), but required the verge to be located so near the crown wheel that the teeth fell on the pallets very near the axis, reducing initial leverage and increasing friction, thus requiring lighter pendulums.

As might be expected from its early invention, the verge is the most inaccurate of the widely used escapements. It suffers from these problems:

Verge escapements were used in virtually all clocks and watches for 400 years. Then the increase in accuracy due to the introduction of the pendulum and balance spring in the mid 17th century focused attention on error caused by the escapement. By the 1820s, the verge was superseded by better escapements, though many examples of mid 19th century verge watches exist, as they were much cheaper by this time.

In pocketwatches, besides its inaccuracy, the vertical orientation of the crown wheel and the need for a bulky fusee made the verge movement unfashionably thick. French watchmakers adopted the thinner cylinder escapement, invented in 1695. In England, high end watches went to the duplex escapement, developed in 1782, but inexpensive verge fusee watches continued to be produced until the mid 19th century, when the lever escapement took over. These later verge watches were colloquially called 'turnips' because of their bulky build.

The verge was only used briefly in pendulum clocks before it was replaced by the anchor escapement, invented around 1660 and widely used beginning in 1680. The problem with the verge was that it required the pendulum to swing in a wide arc of 80° to 100°. Christiaan Huygens in 1674 showed that a pendulum swinging in a wide arc is an inaccurate timekeeper, because its period of swing is sensitive to small changes in the drive force provided by the clock mechanism.

Although the verge is not known for accuracy, it is capable of it. The first successful marine chronometers, H4 and H5, made by John Harrison in 1759 and 1770, used verge escapements with diamond pallets., In trials they were accurate to within a fifth of a second per day.

Today the verge is seen only in antique or antique-replica timepieces. Many original bracket clocks have their Victorian-era anchor escapement conversions undone and the original style of verge escapement restored. Clockmakers call this a verge reconversion.

Now if I can only get the darn thing to work.

From Wikipedia"

The verge (or crown wheel) escapement is the earliest known type of mechanical escapement, the mechanism in a mechanical clock that controls its rate by allowing the gear train to advance at regular intervals or 'ticks'. Its origin is unknown. Verge escapements were used from the 14th century until the mid 19th century in clocks and pocketwatches. The name verge comes from the Latin virga, meaning stick or rod.

Its invention is important in the history of technology, because it made possible the development of all-mechanical clocks. This caused a shift from measuring time by continuous processes, such as the flow of liquid in water clocks, to repetitive, oscillatory processes, such as the swing of pendulums, which had the potential to be more accurate. Oscillating timekeepers are used in all modern timepieces.

The verge escapement dates from 13th-century Europe, where its invention led to the development of the first all-mechanical clocks. Starting in the 13th century, large tower clocks were built in European town squares, cathedrals, and monasteries. They kept time by using the verge escapement to drive the foliot, a primitive type of balance wheel, causing it to oscillate back and forth. The foliot was a horizontal bar with weights on the ends, and the rate of the clock could be adjusted by sliding the weights in or out on the bar.

The verge probably evolved from the alarum, which used the same mechanism to ring a bell and had appeared centuries earlier. There has been speculation that Villard de Honnecourt invented the verge escapement in 1237 with an illustration of a strange mechanism to turn an angel statue to follow the sun with its finger, but the consensus is that this was not an escapement.

It is believed that sometime in the late 13th century the verge escapement mechanism was applied to tower clocks, creating the first mechanical clock. In spite of the fact that these clocks were celebrated objects of civic pride which were written about at the time, it may never be known when the new escapement was first used. This is because it has proven difficult to distinguish from the meager written documentation which of these early tower clocks were mechanical, and which were water clocks; the same Latin word, horologe, was used for both. None of the original mechanisms have survived unaltered. Sources differ on which was the first clock 'known' to be mechanical, depending on which manuscript evidence they regard as conclusive. One candidate is the Dunstable Priory clock in Bedfordshire, England built in 1283, because accounts say it was installed above the rood screen, where it would be difficult to replenish the water needed for a water clock. Another is the clock built at the Palace of the Visconti, Milan, Italy, in 1335. However, there is agreement that mechanical clocks existed by the late 13th century.

The earliest description of an escapement, in Richard of Wallingford's 1327 manuscript Tractatus Horologii Astronomici on the clock he built at the Abbey of St. Albans, was not a verge, but a variation called a 'strob' escapement. It consisted of a pair of escape wheels on the same axle, with alternating radial teeth. The verge rod was suspended between them, with a short crosspiece that rotated first in one direction and then the other as the staggered teeth pushed past. Although no other example is known, it is possible that this design preceded the verge in clocks.

For the first two hundred years or so of the clock's existence, the verge was the only escapement used in mechanical clocks. In the sixteenth century alternative escapements started to appear, but the verge remained the most used escapement for 350 years until mid-17th century advances in mechanics, which also resulted in the invention of the pendulum. Since clocks were valuable, after the invention of the pendulum many verge clocks were rebuilt to use this more accurate timekeeping technology, so very few of the early verge and foliot clocks have survived unaltered to the present day.

How accurate the first verge and foliot clocks were is debatable, with estimates of one to two hours error per day being mentioned, although modern experiments with clocks of this construction show accuracies of minutes per day were achievable. Early verge clocks were probably no more accurate than the previous water clocks, but they did not freeze in winter and were a more promising technology for innovation. By the mid-17th century, when the pendulum replaced the foliot, the best verge and foliot clocks had achieved an accuracy of 15 minutes per day.

Most of the gross inaccuracy of the early verge and foliot clocks was not due to the escapement itself, but to the foliot oscillator. The first use of pendulums in clocks around 1656 suddenly increased the accuracy of the verge clock from hours a day to minutes a day. Most clocks were rebuilt with their foliots replaced by pendulums, to the extent that it is difficult to find original verge and foliot clocks intact today. A similar increase in accuracy in verge watches followed the introduction of the balance spring in 1658.

The verge escapement consists of a wheel shaped like a crown, with sawtooth-shaped teeth protruding axially toward the front, and with its axis oriented horizontally. In front of it is a vertical rod, the verge, with two metal plates, the pallets, that engage the teeth at opposite sides of the crown wheel. The pallets are not parallel, but are oriented with an angle in between them so only one catches the teeth at a time. The balance wheel (or the pendulum) is mounted at the end of the verge rod. As the clock's gears turn the crown wheel, one of its teeth pushes on a pallet, rotating the verge in one direction, and rotating the second pallet into the path of the teeth on the opposite side of the wheel, until the tooth pushes past the first pallet. Then a tooth on the wheel's opposite side contacts the second pallet, rotating the verge back the other direction, and the cycle repeats. The result is to change the rotary motion of the wheel to an oscillating motion of the verge. Each swing of the foliot or pendulum thus allows one tooth of the escape wheel to pass, advancing the wheel train of the clock by a fixed amount, moving the hands forward at a constant rate.

The crown wheel must have an odd number of teeth for the escapement to function. With an even number, two opposing teeth will contact the pallets at the same time, jamming the escapement. The usual angle between the pallets was 90° to 105°, resulting in a foliot or pendulum swing of around 80° to 100°. In order to reduce the pendulum's swing to make it more isochronous, the French used larger pallet angles, upwards of 115°. This reduced the pendulum swing to around 50° and reduced recoil (below), but required the verge to be located so near the crown wheel that the teeth fell on the pallets very near the axis, reducing initial leverage and increasing friction, thus requiring lighter pendulums.

As might be expected from its early invention, the verge is the most inaccurate of the widely used escapements. It suffers from these problems:

- Verge watches and clocks are sensitive to changes in the drive force; they slow down as the mainspring unwinds. This is called lack of isochronism. It was much worse in verge and foliot clocks due to the lack of a balance spring, but is a problem in all verge movements. In fact, the standard method of adjusting the rate of early verge watches was to alter the force of the mainspring. The cause of this problem is that the crown wheel teeth are always pushing on the pallets, driving the pendulum (or balance wheel) throughout its cycle; it is never allowed to swing freely. All verge watches and spring driven clocks required fusees to equalize the force of the mainspring to achieve even minimal accuracy.

- The escapement has "recoil", meaning that the momentum of the foliot or pendulum pushes the crown wheel backward momentarily, causing the clock's wheel train to move backward, during part of its cycle. This increases friction and wear, resulting in inaccuracy. One way to tell whether an antique watch has a verge escapement is to observe the second hand closely; if it moves backward a little during each cycle, the watch is a verge. This is not necessarily the case in clocks, as there are some other pendulum escapements which exhibit recoil.

- In pendulum clocks, the wide pendulum swing angles of 80°-100° required by the verge cause an additional lack of isochronism due to circular error.

- The wide pendulum swings also cause a lot of air friction, reducing the accuracy of the pendulum, and requiring a lot of power to keep it going, increasing wear. So verge pendulum clocks had lighter bobs, which reduced accuracy.

- Verge timepieces tend to accelerate as the crown wheel and the pallets wear down. This is particularly evident in verge watches from the mid-18th century onwards. It is not in the least unusual for these watches, when run today, to gain many hours per day, or to simply spin as if there were no balance present. The reason for this is that as new escapements were invented, it became the fashion to have a thin watch. To achieve this in a verge watch requires the crown wheel to be made very small, magnifying the effects of wear.

Verge escapements were used in virtually all clocks and watches for 400 years. Then the increase in accuracy due to the introduction of the pendulum and balance spring in the mid 17th century focused attention on error caused by the escapement. By the 1820s, the verge was superseded by better escapements, though many examples of mid 19th century verge watches exist, as they were much cheaper by this time.

In pocketwatches, besides its inaccuracy, the vertical orientation of the crown wheel and the need for a bulky fusee made the verge movement unfashionably thick. French watchmakers adopted the thinner cylinder escapement, invented in 1695. In England, high end watches went to the duplex escapement, developed in 1782, but inexpensive verge fusee watches continued to be produced until the mid 19th century, when the lever escapement took over. These later verge watches were colloquially called 'turnips' because of their bulky build.

The verge was only used briefly in pendulum clocks before it was replaced by the anchor escapement, invented around 1660 and widely used beginning in 1680. The problem with the verge was that it required the pendulum to swing in a wide arc of 80° to 100°. Christiaan Huygens in 1674 showed that a pendulum swinging in a wide arc is an inaccurate timekeeper, because its period of swing is sensitive to small changes in the drive force provided by the clock mechanism.

Although the verge is not known for accuracy, it is capable of it. The first successful marine chronometers, H4 and H5, made by John Harrison in 1759 and 1770, used verge escapements with diamond pallets., In trials they were accurate to within a fifth of a second per day.

Today the verge is seen only in antique or antique-replica timepieces. Many original bracket clocks have their Victorian-era anchor escapement conversions undone and the original style of verge escapement restored. Clockmakers call this a verge reconversion.

Tuesday, December 12, 2017

The work of Gord Arnold

Gord Arnold built this Pershing diorama in 1/35 scale with resin figures.

Next we have Gord's Revell 1/25 scale 1970 Torino Cobra 429 Super Cobra Jet.

Next here is Gord's Conversion using a Motor City Resin body over an AMT 1969 Cobra Fastback model kit. Very nice indeed. The paint is Metallic Indian Fire Red by Model Car World. It's a lacquer that is pre-mixed and ready for the air brush.

Next we have Gord's Revell 1/25 scale 1970 Torino Cobra 429 Super Cobra Jet.

Next here is Gord's Conversion using a Motor City Resin body over an AMT 1969 Cobra Fastback model kit. Very nice indeed. The paint is Metallic Indian Fire Red by Model Car World. It's a lacquer that is pre-mixed and ready for the air brush.

Friday, December 8, 2017

8 Years

8 years and counting since I started this blog and I have you to thank for its continuation. Here's to many more.

Thursday, December 7, 2017

Jeannin Stahltaube 1914

Here are some images of Wingnut Wings 1/32 scale Jeannin Stahltaube 1914.

From Wikipedia"

The Etrich Taube, also known by the names of the various later manufacturers who build versions of the type, such as the Rumpler Taube, was a pre-World War I monoplane aircraft. It was the first military aeroplane to be mass-produced in Germany.

The Taube was very popular prior to the First World War, and it was also used by the air forces of Italy and Austria-Hungary. Even the Royal Flying Corps operated at least one Taube in 1912. On November 1, 1911, Giulio Gavotti, an Italian aviator, dropped the world's first aerial bomb from his Taube monoplane over the Ain Zara oasis in Libya. Once the war began, it quickly proved inferior as a serious warplane and as a result was soon replaced by newer and more effective designs.

The Taube was designed in 1909 by Igo Etrich of Austria-Hungary, and first flew in 1910. It was licensed for serial production by Lohner-Werke in Austria and by Edmund Rumpler in Germany, now called the Etrich-Rumpler-Taube. Rumpler soon changed the name to Rumpler-Taube, and stopped paying royalties to Etrich, who subsequently abandoned his patent.

Despite its name, the Taube's unique wing form was not modeled after a dove, but was copied from the seeds of Alsomitra macrocarpa, which can fly long distances from their parent tree. Similar wing shapes were also used by Karl Jatho and Frederick Handley Page. Etrich had tried to build a flying wing aircraft based on the Zanonia wing shape, but the more conventional Taube type, with tail surfaces, was much more successful.

Etrich adopted the format of crosswind-capable main landing gear that Louis Blériot had used on his Blériot XI cross-channel monoplane for better ground handling. The wing has three spars and was braced by a cable-braced steel tube truss (called a "bridge", or Brücke in German) under each wing: at the outer end the uprights of this structure were lengthened to rise above the upper wing surfaces, to form kingposts to carry bracing and warping wires for the enlarged wingtips. A small landing wheel was sometimes mounted on the lower end of this kingpost, to protect it for landings and to help guard against ground loops.

Later Taube-type aircraft from other manufacturers would eventually replace the Blériot-style crosswind main gear with a simpler V-strut main gear format, and also omitted the underwing "bridge" structure for somewhat better aerodynamic efficiency.

Like many contemporary aircraft, especially monoplanes, the Taube used wing warping rather than ailerons for lateral (roll) control, and also warped the rear half of the stabilizer for use as an elevator control surface's function. Only the vertical, twinned triangular rudder surfaces were usually hinged.

The design provided for very stable flight, which made it extremely suitable for observation. In addition, the translucent wings made it difficult for ground observers to detect a Taube at an altitude above 400 meters. The first hostile engagement was by an Italian Taube in 1911 in Libya, its pilot using pistols and dropping 2 kg (4.4 lb) grenades. The Taube was also used for bombing in the Balkans in 1912–13, and in late 1914 when German 3 kg (6.6 lb) bomblets and propaganda leaflets were dropped over Paris. Taube spotter planes detected the advancing Imperial Russian Army in East Prussia during the World War I Battle of Tannenberg.

In civilian use, the Taube was used by pilots to win the Munich-Berlin Kathreiner prize. On 8 December 1911, Gino Linnekogel and Suvelick Johannisthal achieved a two-man endurance record for flying a Taube 4 hours and 35 minutes over Germany.

While initially there were two Taube aircraft assigned to Imperial German units stationed at Qingdao, China only one was available at the start of the war due to an accident. The Rumpler Taube piloted by Lieutenant Gunther Plüschow had to face the attacking Japanese, who had with them a total of eight aircraft. On October 2, 1914, Plüschow's Taube attacked the Japanese warshipswith two small bombs, but failed to score any hits. On November 7, 1914, shortly before the fall of Qingdao, Plüschow was ordered to fly top secret documents to Shanghai, but was forced to make an emergency landing at Lianyungang in Jiangsu, where he was interned by a local Chinese force. Plüschow was rescued by local Chinese civilians under the direction of an American missionary, and successfully reached his destination at Shanghai with his top secret documents, after giving the engine to one of the Chinese civilians who rescued him.

Poor rudder and lateral control made the Taube difficult and slow to turn. The aeroplane proved to be a very easy target for the faster and more mobile Allied fighters of World War I, and just six months into the war, the Taube had been removed from front line service to be used to train new pilots. Many future German aces would learn to fly in a Rumpler Taube.Due to the lack of license fees, no less than 14 companies built a large number of variations of the initial design, making it difficult for historians to determine the exact manufacturer based on historical photographs.

The Technisches Museum Wien is thought to have the only known remaining Etrich-built example of the Taube in existence, an early enough example to have a four-cylinder engine powering it, and is potentially a twin to Gavotti's Taube aircraft from 1911, also said to have been powered with a four-cylinder inline engine. Other examples of original Taubes exist, such as one in Norway, which was the last original Taube to fly under its own power in 1922, over a Norwegian fjord.

The Owl's Head Transportation Museum in Owls Head, Maine USA, is so far the only known museum to attempt the construction of a flyable reproduction of the Etrich Taube in North America. Their example first flew in 1990, and it still flies today with the power of a 200 hp Ranger L-440 inline-6 "uprighted" air-cooled engine.

From Wikipedia"

The Etrich Taube, also known by the names of the various later manufacturers who build versions of the type, such as the Rumpler Taube, was a pre-World War I monoplane aircraft. It was the first military aeroplane to be mass-produced in Germany.

The Taube was very popular prior to the First World War, and it was also used by the air forces of Italy and Austria-Hungary. Even the Royal Flying Corps operated at least one Taube in 1912. On November 1, 1911, Giulio Gavotti, an Italian aviator, dropped the world's first aerial bomb from his Taube monoplane over the Ain Zara oasis in Libya. Once the war began, it quickly proved inferior as a serious warplane and as a result was soon replaced by newer and more effective designs.

The Taube was designed in 1909 by Igo Etrich of Austria-Hungary, and first flew in 1910. It was licensed for serial production by Lohner-Werke in Austria and by Edmund Rumpler in Germany, now called the Etrich-Rumpler-Taube. Rumpler soon changed the name to Rumpler-Taube, and stopped paying royalties to Etrich, who subsequently abandoned his patent.

Despite its name, the Taube's unique wing form was not modeled after a dove, but was copied from the seeds of Alsomitra macrocarpa, which can fly long distances from their parent tree. Similar wing shapes were also used by Karl Jatho and Frederick Handley Page. Etrich had tried to build a flying wing aircraft based on the Zanonia wing shape, but the more conventional Taube type, with tail surfaces, was much more successful.

Etrich adopted the format of crosswind-capable main landing gear that Louis Blériot had used on his Blériot XI cross-channel monoplane for better ground handling. The wing has three spars and was braced by a cable-braced steel tube truss (called a "bridge", or Brücke in German) under each wing: at the outer end the uprights of this structure were lengthened to rise above the upper wing surfaces, to form kingposts to carry bracing and warping wires for the enlarged wingtips. A small landing wheel was sometimes mounted on the lower end of this kingpost, to protect it for landings and to help guard against ground loops.

Later Taube-type aircraft from other manufacturers would eventually replace the Blériot-style crosswind main gear with a simpler V-strut main gear format, and also omitted the underwing "bridge" structure for somewhat better aerodynamic efficiency.

Like many contemporary aircraft, especially monoplanes, the Taube used wing warping rather than ailerons for lateral (roll) control, and also warped the rear half of the stabilizer for use as an elevator control surface's function. Only the vertical, twinned triangular rudder surfaces were usually hinged.

The design provided for very stable flight, which made it extremely suitable for observation. In addition, the translucent wings made it difficult for ground observers to detect a Taube at an altitude above 400 meters. The first hostile engagement was by an Italian Taube in 1911 in Libya, its pilot using pistols and dropping 2 kg (4.4 lb) grenades. The Taube was also used for bombing in the Balkans in 1912–13, and in late 1914 when German 3 kg (6.6 lb) bomblets and propaganda leaflets were dropped over Paris. Taube spotter planes detected the advancing Imperial Russian Army in East Prussia during the World War I Battle of Tannenberg.

In civilian use, the Taube was used by pilots to win the Munich-Berlin Kathreiner prize. On 8 December 1911, Gino Linnekogel and Suvelick Johannisthal achieved a two-man endurance record for flying a Taube 4 hours and 35 minutes over Germany.

While initially there were two Taube aircraft assigned to Imperial German units stationed at Qingdao, China only one was available at the start of the war due to an accident. The Rumpler Taube piloted by Lieutenant Gunther Plüschow had to face the attacking Japanese, who had with them a total of eight aircraft. On October 2, 1914, Plüschow's Taube attacked the Japanese warshipswith two small bombs, but failed to score any hits. On November 7, 1914, shortly before the fall of Qingdao, Plüschow was ordered to fly top secret documents to Shanghai, but was forced to make an emergency landing at Lianyungang in Jiangsu, where he was interned by a local Chinese force. Plüschow was rescued by local Chinese civilians under the direction of an American missionary, and successfully reached his destination at Shanghai with his top secret documents, after giving the engine to one of the Chinese civilians who rescued him.

Poor rudder and lateral control made the Taube difficult and slow to turn. The aeroplane proved to be a very easy target for the faster and more mobile Allied fighters of World War I, and just six months into the war, the Taube had been removed from front line service to be used to train new pilots. Many future German aces would learn to fly in a Rumpler Taube.Due to the lack of license fees, no less than 14 companies built a large number of variations of the initial design, making it difficult for historians to determine the exact manufacturer based on historical photographs.

The Technisches Museum Wien is thought to have the only known remaining Etrich-built example of the Taube in existence, an early enough example to have a four-cylinder engine powering it, and is potentially a twin to Gavotti's Taube aircraft from 1911, also said to have been powered with a four-cylinder inline engine. Other examples of original Taubes exist, such as one in Norway, which was the last original Taube to fly under its own power in 1922, over a Norwegian fjord.

The Owl's Head Transportation Museum in Owls Head, Maine USA, is so far the only known museum to attempt the construction of a flyable reproduction of the Etrich Taube in North America. Their example first flew in 1990, and it still flies today with the power of a 200 hp Ranger L-440 inline-6 "uprighted" air-cooled engine.

Tuesday, December 5, 2017

The Work Of Michael Evans

Here is a funny diorama by Regina modeler Mike Evans. It is called

Zombie Apocalypse. He assembled some cattle stealing ufos, now available

zombie figures, and some converted solders in 1/35 to make an exciting

scene. One fact that I really like about Mr. Evan's work is that he is

not afraid to be political.

Next A couple of bums are standing next to an old wreck in 1/25 scale. I like the graffiti on the car.

Next A couple of bums are standing next to an old wreck in 1/25 scale. I like the graffiti on the car.

Dave Porter's UFO's

The first is the "Bob Lazar" ufo by Testor in 1/48 scale. This is an Area 51 S4 UFO that started all the rage in the early 90's.

Next is the Saucer from the "Invaders" TV series. The kit was released by Aurora, Monogram, Polar lights and now by someone else. There is lots of aftermarket for this kit. Both models were finished in Alclad.

Next is the Saucer from the "Invaders" TV series. The kit was released by Aurora, Monogram, Polar lights and now by someone else. There is lots of aftermarket for this kit. Both models were finished in Alclad.

Saturday, December 2, 2017

USS Spuyten Duyvil

Here are some images of Cottage Industry Models 1/96 scale USS Spuyten Duyvil Union Ironclad ship.

From Wikipedia"

During the American Civil War, the Union Navy suffered heavy losses from the explosion of Confederate torpedoes. This experience prompted the Union Navy to design and build vessels capable of using this new weapon. One effort along this line resulted in a screw steam torpedo boat originally called Stromboli, but later called Spuyten Duyvil, after the Spuyten Duyvil area in New York City.

Stromboli was designed by the Chief Engineer of the United States Navy, Captain William W. Wood, who supervised her construction at New Haven, CT, by Samuel M. Pook. The contract for her construction was dated 1 June 1864. Confirmed records of her launching and commissioning have not been found – though period records indicate that she was completed in only three months. On 19 November 1864, the boat was renamed Spuyten Duyvil. On 25 November 1864, she successfully fired two torpedoes. Late in November 1864, Commodore Charles Stewart Boggs was placed in charge of Spuyten Duyvil, Picket Boat No. 6, and steam tug John T. Jenkins which had been chartered to tow the former vessels to Hampton Roads, VA. Upon arriving at Baltimore, MD on 2 December, Boggs turned the vessels over to Commodore T. A. Dornin who placed them under First Assistant Engineer John L. Lay for the remainder of the trip to Hampton Roads. The vessels arrived at Norfolk, VA on 5 December.

The torpedo boat was ordered up the James River a week later to help assure Union control of that vital waterway during General Ulysses S. Grant's drive on Richmond, VA. She arrived at Akin's Landing on 15 December, and she operated on the upper James slightly below the Confederate obstructions through most of the remaining months of the campaign. A highlight of her service came on the night of 23/24 January 1865 when the Confederacy's James River Squadron launched its downstream assault on the Union squadron. During the ensuing Battle of Trent's Reach, Spuyten Duyvil supported Onondaga, the only monitor then on the river.

After General Robert E. Lee evacuated Richmond, Spuyten Duyvil used her torpedoes to help clear the obstructions from the river. Her work made it possible for President Abraham Lincoln to steam up in Malvern and, after Rear Admiral David Dixon Porter's flagship ran aground, to be rowed in a launch safely to the former Confederate capital.

Following the end of the war, Spuyten Duyvil continued to clear obstructions from the James. She then returned to the New York Navy Yard where she was placed in ordinary in 1866. In the years that followed, she was used for developmental work and was modified with many experimental improvements. The ship disappeared from the Navy list in 1880.

In this case, as in the common use of the term in the 19th century, torpedo refers to a device sometimes rigged as a spar torpedo that would now be considered to be a type of naval mine, not being the self-propelled device (called a locomotive torpedo) common in the 20th century.

From Wikipedia"

During the American Civil War, the Union Navy suffered heavy losses from the explosion of Confederate torpedoes. This experience prompted the Union Navy to design and build vessels capable of using this new weapon. One effort along this line resulted in a screw steam torpedo boat originally called Stromboli, but later called Spuyten Duyvil, after the Spuyten Duyvil area in New York City.

Stromboli was designed by the Chief Engineer of the United States Navy, Captain William W. Wood, who supervised her construction at New Haven, CT, by Samuel M. Pook. The contract for her construction was dated 1 June 1864. Confirmed records of her launching and commissioning have not been found – though period records indicate that she was completed in only three months. On 19 November 1864, the boat was renamed Spuyten Duyvil. On 25 November 1864, she successfully fired two torpedoes. Late in November 1864, Commodore Charles Stewart Boggs was placed in charge of Spuyten Duyvil, Picket Boat No. 6, and steam tug John T. Jenkins which had been chartered to tow the former vessels to Hampton Roads, VA. Upon arriving at Baltimore, MD on 2 December, Boggs turned the vessels over to Commodore T. A. Dornin who placed them under First Assistant Engineer John L. Lay for the remainder of the trip to Hampton Roads. The vessels arrived at Norfolk, VA on 5 December.

The torpedo boat was ordered up the James River a week later to help assure Union control of that vital waterway during General Ulysses S. Grant's drive on Richmond, VA. She arrived at Akin's Landing on 15 December, and she operated on the upper James slightly below the Confederate obstructions through most of the remaining months of the campaign. A highlight of her service came on the night of 23/24 January 1865 when the Confederacy's James River Squadron launched its downstream assault on the Union squadron. During the ensuing Battle of Trent's Reach, Spuyten Duyvil supported Onondaga, the only monitor then on the river.

After General Robert E. Lee evacuated Richmond, Spuyten Duyvil used her torpedoes to help clear the obstructions from the river. Her work made it possible for President Abraham Lincoln to steam up in Malvern and, after Rear Admiral David Dixon Porter's flagship ran aground, to be rowed in a launch safely to the former Confederate capital.

Following the end of the war, Spuyten Duyvil continued to clear obstructions from the James. She then returned to the New York Navy Yard where she was placed in ordinary in 1866. In the years that followed, she was used for developmental work and was modified with many experimental improvements. The ship disappeared from the Navy list in 1880.

In this case, as in the common use of the term in the 19th century, torpedo refers to a device sometimes rigged as a spar torpedo that would now be considered to be a type of naval mine, not being the self-propelled device (called a locomotive torpedo) common in the 20th century.

Friday, November 24, 2017

The Work Of Dave Porter

Here is an image of Dave Porter's Testors 1/24 scale Pantera and Minicraft's 1/144 scale Boeing B52-H and Italeri's 1/35 scale Panzer 4 and here in his own words are his descriptions.

Here is the 1/144 B-52H from Minicraft. The kit fit okay but I had to create twenty four antenna to make it look current.

This a better picture of a Testor 1/24 Pantera. I made it into a club racer. The wheels and tires are Fujimi aftermarket. The interior has race harness and fire extinguisher added. The exterior is Tamiya acrylic metallic blue With Testor "one coat" clear applied then polished.

I have a 1/35 scale Panzer 4 By Italeri. The kit is built from the box. The driver is from Warriors.

Next is a JU-88G late model night fighter. This was a very high performance aircraft. It's existence is why the HE-219 was cancelled. The model is by Zvezda and is in 1/72 scale. It fit well. I added some Eduard belts and finished the model in Tamiya acrylics.

Next - Tamiya Brumbarin 1/35 built straight out of box. I finished the model in acrylics, oil paint and pastel dust.

Next we have Trumpeters 1/48 scale Supermarine Spiteful. The replacement for the Spitfire of which it was developed from.

Next is Monogram's 1/24 scale Cobra racer. Nice model but the wheels could be a bit deeper. I finished the model in lacquer color and clear.

Next is a multimedia model of a 1975 Greenwood Corvette race car. The kit is mostly resin with a few white metal castings plus a sheet of brass. The car is by Scale Designs and is in 1/25 scale. It is finished in white lacquer. The kit includes decals for "The Spirit Of 76" and some nice looking duct tape. Rock players will know what I'm talking about.

Next we have the Boeing X-32 Strike Fighter candidate that lost to the F-35. This 1/72nd scale kit is from Italeri. It didn't fit well but it's nice

when finished. The paint scheme is a fictitious Ferris design. The aircraft is just too ugly to have it displayed with the landing gear down.

Wednesday, November 8, 2017

Bachem Ba 349 "Natter"

Here are some images of Fly Models 1/32 scale Bachem Ba 349 "Natter".

From Wikipedia"

The Bachem Ba 349 Natter (English: Colubrid, grass-snake) was a World War II German point-defence rocket-powered interceptor, which was to be used in a very similar way to a manned surface-to-air missile. After a vertical take-off, which eliminated the need for airfields, most of the flight to the Allied bombers was to be controlled by an autopilot. The primary role of the relatively untrained pilot was to aim the aircraft at its target bomber and fire its armament of rockets. The pilot and the fuselage containing the rocket-motor would then land using separate parachutes, while the nose section was disposable. The only manned vertical take-off flight on 1 March 1945 ended in the death of the test pilot, Lothar Sieber.

In 1943 Luftwaffe air superiority was being challenged by the Allies over the Reich and radical innovations were required to overcome the crisis. Surface-to-air missiles appeared to be a promising approach to counter the Allied strategic bombing offensive; a variety of projects were started, but invariably problems with the guidance and homing systems prevented any of these from attaining operational status. Providing the missile with a pilot, who could operate a weapon during the brief terminal approach phase, offered a solution. Submissions for a simple target defence interceptor were requested by the Luftwaffe in early 1944 under the umbrella of the "Emergency Fighter Program". A number of simple designs were proposed, including the Heinkel P.1077 Julia, in which the pilot lay prone (on his stomach), to reduce the frontal area. The Julia was the front-runner for the contract. The initial plan was to launch the aircraft vertically, but this concept was later changed to a conventional horizontal take-off from a tricycle-wheeled trolley, similar to that used by the first eight prototypes of the Arado Ar 234 jet reconnaissance bomber.

Erich Bachem's BP-20 ("Natter") was a development from a design he had worked on at Fieseler, the Fi 166 concept, but considerably more radical than the other submissions. It was built using glued and nailed wooden parts with an armour-plated bulkhead and bulletproof glass windshield at the front of the cockpit. The initial plan was to power the machine with a Walter HWK 109-509A-2 rocket motor; however, only the 109-509A-1, as used in the Me 163, was available.[7] It had a sea level thrust variable between 100 kg (220 lb) at "idle" to 1,600 kg (3,500 lb) at full power, with the Natter's intended quartet of rear flank-mount Schmidding SG34 solid fuel rocket boosters used in its vertical launch to provide an additional 4,800 kg (10,600 lb) thrust for 10 seconds before they burned out and were jettisoned. The experimental prototypes slid up a 20 m (66 ft)-tall vertical steel launch tower for a maximum sliding length of 17 m (56 ft) in three guideways, one for each wing tip and one for the lower tip of the ventral tail fin. By the time the aircraft left the tower it was hoped that it would have achieved sufficient speed to allow its aerodynamic surfaces to provide stable flight.

Under operational conditions, once the Natter had left the launcher, it would be guided to the proximity of the Allied bombers by an autopilot with the possibility of an added beam guidance similar to that used in some V-2 rocket launches. Only then would the pilot take control, aim and fire the armament, which was originally proposed to be a salvo of 19 R4M rockets. Later, 28 R4Ms or a number of Henschel Hs 297 Föhn rockets were suggested, with either variety of unguided rocket fired from the Natter's nose-mount cellular launch tubes contained in its nose. The Natter was intended to fly up and over the bombers, by which time its Walter motor would probably be out of propellant. Following its one-time attack with its rockets, the pilot would dive his Natter, now effectively a glider, to an altitude of around 3,000 m (9,800 ft), flatten out, release the nose of the aircraft and a small braking parachute from the rear fuselage. The fuselage would decelerate and the pilot would be ejected forwards by his own inertia and land by means of a personal parachute.

In an early proposal in August 1944, the Natter design had a concrete nose; it was suggested that the machine might ram a bomber, but this proposal was subsequently withdrawn in later Project Natter outlines. Bachem stated clearly in the initial proposal that the Natter was not a suicide weapon and much effort went into designing safety features for the pilot. However, owing to the potential dangers for the pilot inherent in the operation of this precarious aircraft, the Natter is sometimes listed as a suicide craft. The design had one decisive advantage over its competitors – it eliminated the necessity to land an unpowered gliding machine at an airbase, which, as the history of the Me 163 rocket aircraft had clearly demonstrated, made an aircraft extremely vulnerable to attack by Allied fighters.

Construction of the first experimental prototype Natter, Versuchsmuster 1, was completed on 4 October 1944. V1 was subsequently referred to as Baumuster1 (BM1) and later still the "B" was dropped and the machine became known as the M1. Most subsequent prototypes were known by 'M' codes, as the later prototypes of the Heinkel He 162 were. Manned glider flights began on 3 November 1944. The first glider M1 was towed to around 3,000 m by a Heinkel He 111 bomber with a cable (Tragschlepp mode) at Neuburg an der Donau. The pilot was Erich Klöckner, who made all four documented Tragschlepp flights. After carrying out the test programme of the M1, he bailed out and the machine crashed into the ground. It was found that, unfortunately, the towing cable, and in the case of the M3, the undercarriage interfered with the flight characteristics of the gliders and consequently the results were difficult to interpret. To clear any lingering doubts about the Natter in the glider mode, Hans Zübert made a daring free flight in the M8 on the 14 February, and showed that the Natter was indeed a very good flying machine.

The vertical take-off (VTO) trials were conducted on high ground called the Ochsenkopf at the Truppenübungsplatz (military training area) Heuberg near Stetten am kalten Markt, Württemberg. The first successful unmanned vertical take-off from the experimental launch tower occurred on 22 December 1944. The test machine, the M16, was powered only by the Schmidding solid boosters, as were all the early VTO trials. Up to and including 1 March 1945, 16 prototypes had been used, eight in glider trials and eight in VTO trials.

By January 1945 Bachem was under pressure from the authorities in Berlin to carry out a manned VTO flight by the end of February. On 25 February, M22 was in the experimental launch tower. It was as complete an operational machine as possible with the Walter HWK 109-509 A1 motor installed for the first time. A dummy pilot was in the cockpit. Lift-off from the tower was perfect. The engineers and ground crew watched as the M22 ascended under the combined power of the four Schmidding boosters and the Walter motor, an estimated total thrust of 6,500 kg (14,300 lb). The nose separated as programmed and the dummy pilot descended "safely" under its personal parachute. The remainder of the fuselage came down under its two large salvage parachutes, but when it hit the ground the Walter liquid-propellant rocket motor's residual hypergolic propellants (T-Stoff oxidizer and C-Stoff fuel) exploded and the machine was destroyed.

Despite Bachem's concerns that the test programme had been significantly cut short, a young volunteer Luftwaffe test pilot, Lothar Sieber, climbed into the cockpit of the fully fuelled M23 on 1 March. The aircraft was equipped with an FM transmitter for the purpose of transmitting flight data from various monitoring sensors in the machine.

A hard wire intercom appears to have been provided between Sieber and the engineers in the launch bunker using a system similar to that used in the manned glider flights. Around 1100 am, the M23 was ready for take-off. Low stratus clouds lay over the Ocksenkopf. The Walter liquid-fueled rocket motor built up to full thrust and Sieber pushed the button to ignite the four solid boosters. With a roar, the M23 rose out of a cloud of steam and rocket smoke straight up, displaying its camouflage paintwork. At an altitude of about 100 to 150 m (330 to 490 ft), the Natter suddenly pitched backwards into an inverted curve. Initially it climbed at about 30° to the vertical. At about 500 m (1,600 ft) the cockpit canopy was seen to fly off. The Natter continued to climb at high speed at an angle of 15° from the horizontal and disappeared into the clouds. The Walter motor stalled about 15 seconds after take-off. It is estimated the Natter reached 1,500 m (4,900 ft), at which point it nose-dived and hit the ground with great force about 32 seconds later, some kilometres from the launch site. Unknown at the time, one of the Schmidding boosters failed to jettison and its remains were dug up at the crash site in 1998.

Bachem surmised Sieber had involuntarily pulled back on the control column under the effect of the 3 G acceleration. Examination of the canopy, which fell near the launch site, showed the tip of the latch was bent, suggesting it may not have been in the fully closed position at launch. The pilot's headrest had been attached to the underside of the canopy and as the canopy flew off the pilot's head would have snapped back suddenly about 25 cm (9.8 in), hitting the solid wooden rear upper cockpit bulkhead, and either knocking Sieber unconscious or breaking his neck.

This tragedy reinforced Bachem's long held belief that the take-off and flight in the vicinity of the target bombers should be fully automated. The canopy latch was strengthened and the headrest was attached to the backboard of the cockpit. Before the introduction of the autopilot in the test programme, the control column would have a temporary locking device on it, which would allow the machine to ascend vertically to at least 1,000 m (3,300 ft) and then be removed by the pilot. The Walter motor probably ceased operation because the Natter was virtually upside-down and air may have entered the intake pipes in the propellant tanks, starving the motor. Sieber had become the first man to take off vertically from the ground under pure rocket power, some 16 years before Yuri Gagarin's Vostok 1 pioneering, peacetime orbital flight.

Much debate has surrounded the number of Natters built at the Bachem-Werk and their disposition. According to Bachem, 36 Natters were produced at the Bachem-Werk in Waldsee by the end of the war. Up to April 1945, 17 aircraft had been used in unmanned trials comprising five gliders, all slung under an He 111 in the Mistelschlepp configuration prior to launch, and 12 VTO examples. Five aircraft were prepared for manned trials, four gliders and one VTO version. The M3 was flown twice, and then rebuilt at which time it was given the new code BM3a but was never flown. The total number of launches to early April 1945 was 22, as was the total number of Natters constructed up to that time. Bachem reported further that there were 14 more finished or almost finished aircraft in April 1945. Four of these were prototype A1 operational Natters built for test launching from a wooden pole launcher, which had been designed for field deployment. This new launcher was also constructed on the Heuberg, not far from the experimental steel tower. There is documentary evidence for two pole launches in April but not three as claimed by Bachem in his post-war presentation. The documentation for this third flight may have been destroyed by the SS at war's end. Ten A1 operational Natters, called K-Maschinen, were constructed for the Krokus-Einsatz ("Operation Crocus").

The fate of these 14 A1 Natters was as follows: Three were fired from the pole launcher according to Bachem, four were burnt at Waldsee, two were burnt at Lager Schlatt, Oetztal, Austria, four were captured by US troops at Sankt Leonhard im Pitztal, Austria and one, which had been sent as a sample model to a new factory in Thuringia, was captured by the Red Army. Consequently, the total of 36 test and operational aircraft constructed at the Bachem-Werk can be accounted for. However, Natter carcasses were used for a variety of ground-based purposes; for example, as a static booster rocket, armament and strength testing and pilot seat position tests. Some fuselages were reused after flight testing; for example, the M5, 6 and 7.

Of the four Natters captured at Sankt Leonhard im Pitztal, two went to the United States. Only one original Natter built in Germany in the Second World War survives in storage at the Paul E. Garber Preservation, Restoration, and Storage Facility in Suitland, Maryland, under the auspices of the Smithsonian Institution. The fate of the other Natter brought to the US is unknown. There is no documentary evidence that a Natter was ever flown from Muroc Field. The tail section of one of the Natters at Sankt Leonhard im Pitztal was broken off while it still rested on its trailer. The remaining machine was possibly destroyed when the CIOS Field Team left the area. Despite being promised one of these Natters, there is no evidence that a machine ever reached UK shores.

In early February 1945 the positions of the centre of gravity for the A1 operational machine during its flight profile were giving the RLM and the SS cause for concern. They wanted these figures to be decided upon for the upcoming construction of the A1 aircraft for Krokus-Einsatz (Operation Crocus), the field deployment of the Natter. The position of the centre of gravity is expressed as a percentage of the chord (distance between the leading and trailing edges) of the main wing. Thus 0% is the leading edge and 100% is the trailing edge. In the manned glider trials the centre of gravity had been varied between 20 and 34%. At a meeting of engineers held on 8 February, the variations in the centre of gravity expected in the A1 Krokus machine were discussed. At take-off with the weight of the four solid boosters, the centre of gravity would be brought back to 65%, but after releasing these rockets it would move forwards to 22%. The free flight by Zübert on 14 February had showed unequivocally that the little Natter had excellent flying characteristics as a glider. The centre of gravity problem was solved initially by the addition of one-metre-square auxiliary tailfins that were released simultaneously with the jettisoning of the boosters. The Krokus aircraft had vanes that would direct the Walter rocket exhaust gases so as to assist vehicle stabilisation at low speed similar to those used in the V-2 rocket.

French forces had captured Waldsee by 25 April 1945 and presumably took control of the Bachem-Werk. Shortly before the French troops arrived, a group of Bachem-Werk personnel set out for Austria with five A1 Natters on trailers.[43][44] At Bad Wörishofen, the group waited for another squad retreating from Nabern unter Teck with one completed Natter. Both groups then set out for the Austrian Alps. One group with two Natters ended up at the junction of the river Inn and one of its tributaries, the Ötztaler Ache, at Camp Schlatt. The other group went to St. Leonhard im Pitztal with four aircraft. US troops captured the first group at Camp Schlatt around 4 May and the second group on the following day.

At some time during the project, the Bachem-Werk was ordered to give complete details of the BP-20 Natter to the Japanese, but there was doubt over whether they had received them. They were, however, known to have a general knowledge of the Natter and showed considerable interest in the project.

Only one original A1 Natter survives; it is stored in the Paul E. Garber Preservation, Restoration, and Storage Facility in Suitland, Maryland, USA. It is in a poor state of repair and is no longer accessible to the general public. The evidence supports the proposition that this machine was captured by US troops at St. Leonhard im Pitztal, Austria in May 1945. The Natter displayed at the Deutsches Museum is said to have been reconstructed partly from sub-assemblies that survived the end of the war. This machine is of the experimental type as launched from the steel tower and is painted to look like an M17. There are several static reproductions of Natters around the world, for example at the Planes of Fame Air Museum, Chino, California and Fantasy of Flight, Polk City, Florida, US

From Wikipedia"

The Bachem Ba 349 Natter (English: Colubrid, grass-snake) was a World War II German point-defence rocket-powered interceptor, which was to be used in a very similar way to a manned surface-to-air missile. After a vertical take-off, which eliminated the need for airfields, most of the flight to the Allied bombers was to be controlled by an autopilot. The primary role of the relatively untrained pilot was to aim the aircraft at its target bomber and fire its armament of rockets. The pilot and the fuselage containing the rocket-motor would then land using separate parachutes, while the nose section was disposable. The only manned vertical take-off flight on 1 March 1945 ended in the death of the test pilot, Lothar Sieber.

In 1943 Luftwaffe air superiority was being challenged by the Allies over the Reich and radical innovations were required to overcome the crisis. Surface-to-air missiles appeared to be a promising approach to counter the Allied strategic bombing offensive; a variety of projects were started, but invariably problems with the guidance and homing systems prevented any of these from attaining operational status. Providing the missile with a pilot, who could operate a weapon during the brief terminal approach phase, offered a solution. Submissions for a simple target defence interceptor were requested by the Luftwaffe in early 1944 under the umbrella of the "Emergency Fighter Program". A number of simple designs were proposed, including the Heinkel P.1077 Julia, in which the pilot lay prone (on his stomach), to reduce the frontal area. The Julia was the front-runner for the contract. The initial plan was to launch the aircraft vertically, but this concept was later changed to a conventional horizontal take-off from a tricycle-wheeled trolley, similar to that used by the first eight prototypes of the Arado Ar 234 jet reconnaissance bomber.

Erich Bachem's BP-20 ("Natter") was a development from a design he had worked on at Fieseler, the Fi 166 concept, but considerably more radical than the other submissions. It was built using glued and nailed wooden parts with an armour-plated bulkhead and bulletproof glass windshield at the front of the cockpit. The initial plan was to power the machine with a Walter HWK 109-509A-2 rocket motor; however, only the 109-509A-1, as used in the Me 163, was available.[7] It had a sea level thrust variable between 100 kg (220 lb) at "idle" to 1,600 kg (3,500 lb) at full power, with the Natter's intended quartet of rear flank-mount Schmidding SG34 solid fuel rocket boosters used in its vertical launch to provide an additional 4,800 kg (10,600 lb) thrust for 10 seconds before they burned out and were jettisoned. The experimental prototypes slid up a 20 m (66 ft)-tall vertical steel launch tower for a maximum sliding length of 17 m (56 ft) in three guideways, one for each wing tip and one for the lower tip of the ventral tail fin. By the time the aircraft left the tower it was hoped that it would have achieved sufficient speed to allow its aerodynamic surfaces to provide stable flight.

Under operational conditions, once the Natter had left the launcher, it would be guided to the proximity of the Allied bombers by an autopilot with the possibility of an added beam guidance similar to that used in some V-2 rocket launches. Only then would the pilot take control, aim and fire the armament, which was originally proposed to be a salvo of 19 R4M rockets. Later, 28 R4Ms or a number of Henschel Hs 297 Föhn rockets were suggested, with either variety of unguided rocket fired from the Natter's nose-mount cellular launch tubes contained in its nose. The Natter was intended to fly up and over the bombers, by which time its Walter motor would probably be out of propellant. Following its one-time attack with its rockets, the pilot would dive his Natter, now effectively a glider, to an altitude of around 3,000 m (9,800 ft), flatten out, release the nose of the aircraft and a small braking parachute from the rear fuselage. The fuselage would decelerate and the pilot would be ejected forwards by his own inertia and land by means of a personal parachute.

In an early proposal in August 1944, the Natter design had a concrete nose; it was suggested that the machine might ram a bomber, but this proposal was subsequently withdrawn in later Project Natter outlines. Bachem stated clearly in the initial proposal that the Natter was not a suicide weapon and much effort went into designing safety features for the pilot. However, owing to the potential dangers for the pilot inherent in the operation of this precarious aircraft, the Natter is sometimes listed as a suicide craft. The design had one decisive advantage over its competitors – it eliminated the necessity to land an unpowered gliding machine at an airbase, which, as the history of the Me 163 rocket aircraft had clearly demonstrated, made an aircraft extremely vulnerable to attack by Allied fighters.

Construction of the first experimental prototype Natter, Versuchsmuster 1, was completed on 4 October 1944. V1 was subsequently referred to as Baumuster1 (BM1) and later still the "B" was dropped and the machine became known as the M1. Most subsequent prototypes were known by 'M' codes, as the later prototypes of the Heinkel He 162 were. Manned glider flights began on 3 November 1944. The first glider M1 was towed to around 3,000 m by a Heinkel He 111 bomber with a cable (Tragschlepp mode) at Neuburg an der Donau. The pilot was Erich Klöckner, who made all four documented Tragschlepp flights. After carrying out the test programme of the M1, he bailed out and the machine crashed into the ground. It was found that, unfortunately, the towing cable, and in the case of the M3, the undercarriage interfered with the flight characteristics of the gliders and consequently the results were difficult to interpret. To clear any lingering doubts about the Natter in the glider mode, Hans Zübert made a daring free flight in the M8 on the 14 February, and showed that the Natter was indeed a very good flying machine.

The vertical take-off (VTO) trials were conducted on high ground called the Ochsenkopf at the Truppenübungsplatz (military training area) Heuberg near Stetten am kalten Markt, Württemberg. The first successful unmanned vertical take-off from the experimental launch tower occurred on 22 December 1944. The test machine, the M16, was powered only by the Schmidding solid boosters, as were all the early VTO trials. Up to and including 1 March 1945, 16 prototypes had been used, eight in glider trials and eight in VTO trials.

By January 1945 Bachem was under pressure from the authorities in Berlin to carry out a manned VTO flight by the end of February. On 25 February, M22 was in the experimental launch tower. It was as complete an operational machine as possible with the Walter HWK 109-509 A1 motor installed for the first time. A dummy pilot was in the cockpit. Lift-off from the tower was perfect. The engineers and ground crew watched as the M22 ascended under the combined power of the four Schmidding boosters and the Walter motor, an estimated total thrust of 6,500 kg (14,300 lb). The nose separated as programmed and the dummy pilot descended "safely" under its personal parachute. The remainder of the fuselage came down under its two large salvage parachutes, but when it hit the ground the Walter liquid-propellant rocket motor's residual hypergolic propellants (T-Stoff oxidizer and C-Stoff fuel) exploded and the machine was destroyed.

Despite Bachem's concerns that the test programme had been significantly cut short, a young volunteer Luftwaffe test pilot, Lothar Sieber, climbed into the cockpit of the fully fuelled M23 on 1 March. The aircraft was equipped with an FM transmitter for the purpose of transmitting flight data from various monitoring sensors in the machine.

A hard wire intercom appears to have been provided between Sieber and the engineers in the launch bunker using a system similar to that used in the manned glider flights. Around 1100 am, the M23 was ready for take-off. Low stratus clouds lay over the Ocksenkopf. The Walter liquid-fueled rocket motor built up to full thrust and Sieber pushed the button to ignite the four solid boosters. With a roar, the M23 rose out of a cloud of steam and rocket smoke straight up, displaying its camouflage paintwork. At an altitude of about 100 to 150 m (330 to 490 ft), the Natter suddenly pitched backwards into an inverted curve. Initially it climbed at about 30° to the vertical. At about 500 m (1,600 ft) the cockpit canopy was seen to fly off. The Natter continued to climb at high speed at an angle of 15° from the horizontal and disappeared into the clouds. The Walter motor stalled about 15 seconds after take-off. It is estimated the Natter reached 1,500 m (4,900 ft), at which point it nose-dived and hit the ground with great force about 32 seconds later, some kilometres from the launch site. Unknown at the time, one of the Schmidding boosters failed to jettison and its remains were dug up at the crash site in 1998.

Bachem surmised Sieber had involuntarily pulled back on the control column under the effect of the 3 G acceleration. Examination of the canopy, which fell near the launch site, showed the tip of the latch was bent, suggesting it may not have been in the fully closed position at launch. The pilot's headrest had been attached to the underside of the canopy and as the canopy flew off the pilot's head would have snapped back suddenly about 25 cm (9.8 in), hitting the solid wooden rear upper cockpit bulkhead, and either knocking Sieber unconscious or breaking his neck.

This tragedy reinforced Bachem's long held belief that the take-off and flight in the vicinity of the target bombers should be fully automated. The canopy latch was strengthened and the headrest was attached to the backboard of the cockpit. Before the introduction of the autopilot in the test programme, the control column would have a temporary locking device on it, which would allow the machine to ascend vertically to at least 1,000 m (3,300 ft) and then be removed by the pilot. The Walter motor probably ceased operation because the Natter was virtually upside-down and air may have entered the intake pipes in the propellant tanks, starving the motor. Sieber had become the first man to take off vertically from the ground under pure rocket power, some 16 years before Yuri Gagarin's Vostok 1 pioneering, peacetime orbital flight.

Much debate has surrounded the number of Natters built at the Bachem-Werk and their disposition. According to Bachem, 36 Natters were produced at the Bachem-Werk in Waldsee by the end of the war. Up to April 1945, 17 aircraft had been used in unmanned trials comprising five gliders, all slung under an He 111 in the Mistelschlepp configuration prior to launch, and 12 VTO examples. Five aircraft were prepared for manned trials, four gliders and one VTO version. The M3 was flown twice, and then rebuilt at which time it was given the new code BM3a but was never flown. The total number of launches to early April 1945 was 22, as was the total number of Natters constructed up to that time. Bachem reported further that there were 14 more finished or almost finished aircraft in April 1945. Four of these were prototype A1 operational Natters built for test launching from a wooden pole launcher, which had been designed for field deployment. This new launcher was also constructed on the Heuberg, not far from the experimental steel tower. There is documentary evidence for two pole launches in April but not three as claimed by Bachem in his post-war presentation. The documentation for this third flight may have been destroyed by the SS at war's end. Ten A1 operational Natters, called K-Maschinen, were constructed for the Krokus-Einsatz ("Operation Crocus").

The fate of these 14 A1 Natters was as follows: Three were fired from the pole launcher according to Bachem, four were burnt at Waldsee, two were burnt at Lager Schlatt, Oetztal, Austria, four were captured by US troops at Sankt Leonhard im Pitztal, Austria and one, which had been sent as a sample model to a new factory in Thuringia, was captured by the Red Army. Consequently, the total of 36 test and operational aircraft constructed at the Bachem-Werk can be accounted for. However, Natter carcasses were used for a variety of ground-based purposes; for example, as a static booster rocket, armament and strength testing and pilot seat position tests. Some fuselages were reused after flight testing; for example, the M5, 6 and 7.

Of the four Natters captured at Sankt Leonhard im Pitztal, two went to the United States. Only one original Natter built in Germany in the Second World War survives in storage at the Paul E. Garber Preservation, Restoration, and Storage Facility in Suitland, Maryland, under the auspices of the Smithsonian Institution. The fate of the other Natter brought to the US is unknown. There is no documentary evidence that a Natter was ever flown from Muroc Field. The tail section of one of the Natters at Sankt Leonhard im Pitztal was broken off while it still rested on its trailer. The remaining machine was possibly destroyed when the CIOS Field Team left the area. Despite being promised one of these Natters, there is no evidence that a machine ever reached UK shores.

In early February 1945 the positions of the centre of gravity for the A1 operational machine during its flight profile were giving the RLM and the SS cause for concern. They wanted these figures to be decided upon for the upcoming construction of the A1 aircraft for Krokus-Einsatz (Operation Crocus), the field deployment of the Natter. The position of the centre of gravity is expressed as a percentage of the chord (distance between the leading and trailing edges) of the main wing. Thus 0% is the leading edge and 100% is the trailing edge. In the manned glider trials the centre of gravity had been varied between 20 and 34%. At a meeting of engineers held on 8 February, the variations in the centre of gravity expected in the A1 Krokus machine were discussed. At take-off with the weight of the four solid boosters, the centre of gravity would be brought back to 65%, but after releasing these rockets it would move forwards to 22%. The free flight by Zübert on 14 February had showed unequivocally that the little Natter had excellent flying characteristics as a glider. The centre of gravity problem was solved initially by the addition of one-metre-square auxiliary tailfins that were released simultaneously with the jettisoning of the boosters. The Krokus aircraft had vanes that would direct the Walter rocket exhaust gases so as to assist vehicle stabilisation at low speed similar to those used in the V-2 rocket.

French forces had captured Waldsee by 25 April 1945 and presumably took control of the Bachem-Werk. Shortly before the French troops arrived, a group of Bachem-Werk personnel set out for Austria with five A1 Natters on trailers.[43][44] At Bad Wörishofen, the group waited for another squad retreating from Nabern unter Teck with one completed Natter. Both groups then set out for the Austrian Alps. One group with two Natters ended up at the junction of the river Inn and one of its tributaries, the Ötztaler Ache, at Camp Schlatt. The other group went to St. Leonhard im Pitztal with four aircraft. US troops captured the first group at Camp Schlatt around 4 May and the second group on the following day.

At some time during the project, the Bachem-Werk was ordered to give complete details of the BP-20 Natter to the Japanese, but there was doubt over whether they had received them. They were, however, known to have a general knowledge of the Natter and showed considerable interest in the project.

Only one original A1 Natter survives; it is stored in the Paul E. Garber Preservation, Restoration, and Storage Facility in Suitland, Maryland, USA. It is in a poor state of repair and is no longer accessible to the general public. The evidence supports the proposition that this machine was captured by US troops at St. Leonhard im Pitztal, Austria in May 1945. The Natter displayed at the Deutsches Museum is said to have been reconstructed partly from sub-assemblies that survived the end of the war. This machine is of the experimental type as launched from the steel tower and is painted to look like an M17. There are several static reproductions of Natters around the world, for example at the Planes of Fame Air Museum, Chino, California and Fantasy of Flight, Polk City, Florida, US

Monday, November 6, 2017

Brewster Buffalo F2A-1

Here are some images of Special Hobby's 1/32 scale F2A-1 Brewster Buffalo in McClelland Barclay's No. 2 Dazzle Paint scheme.

I wanted to do the more fancy McClelland Barcly's No.1 Dazzle Scheme, but it had been done a few times already. So I decided to do the No. 2 scheme. From Wikipedia"

The Brewster F2A Buffalo was an American fighter aircraft which saw service early in World War II. Designed and built by the Brewster Aeronautical Corporation, it was one of the first U.S. monoplanes with an arrestor hook and other modifications for aircraft carriers. The Buffalo won a competition against the Grumman F4F Wildcat in 1939 to become the U.S. Navy's first monoplane fighter aircraft. Although superior to the Grumman F3F biplane it replaced and the early F4Fs, the Buffalo was largely obsolete when the United States entered the war, being unstable and overweight, especially when compared to the Japanese Mitsubishi A6M Zero.

Several nations, including Finland, Belgium, Britain and the Netherlands, ordered the Buffalo. The Finns were the most successful with their Buffalos, flying them in combat against early Soviet fighters with excellent results. During the Continuation War of 1941–1944, the B-239s (a de-navalized F2A-1) operated by the Finnish Air Force proved capable of engaging and destroying most types of Soviet fighter aircraft operating against Finland at that time and achieving in the first phase of that conflict 32 Soviet aircraft shot down for every B-239 lost, and producing 36 Buffalo "aces".

In December 1941, Buffalos operated by both British Commonwealth (B-339E) and Dutch (B-339D) air forces in South East Asia suffered severe losses in combat against the Japanese Navy's Mitsubishi A6M Zero and the Japanese Army's Nakajima Ki-43 "Oscar". The British attempted to lighten their Buffalos by removing ammunition and fuel and installing lighter guns to improve performance, but it made little difference. After the first few engagements, the Dutch halved the fuel and ammunition load in the wing, which allowed their Buffalos (and their Hurricanes) to stay with the Oscars in turns.

The Buffalo was built in three variants for the U.S. Navy: the F2A-1, F2A-2 and F2A-3. (In foreign service, with lower horsepower engines, these types were designated B-239, B-339, and B-339-23 respectively.) The F2A-3 variant saw action with United States Marine Corps (USMC) squadrons at the Battle of Midway. Shown by the experience of Midway to be no match for the Zero, the F2A-3 was derided by USMC pilots as a "flying coffin." However, the F2A-3s performance was substantially inferior to the F2A-2 variant used by the Navy before the outbreak of the war despite detail improvements.